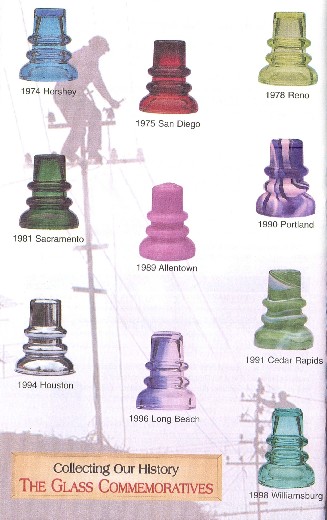

Three Decades of Memories -The History of the National Show Glass Commemoratives

Reprinted from "Crown Jewels of the Wire", May 1999, page 43

The Commemorative Originators, Frank and Margaret Miller

(Part III)

The "Turn" and Glass Production

Glass production time is purchased in "turns." A turn is a

four-hour period of time. The 1970 and 1971 runs were, of course, a very small

operation at Overmyer-Perram in Tulsa. From 1972 through 1983 a very controlled

production run took place. Frank Miller would arrive with the mould from Tulsa,

the commemorative would be run for four hours, and Frank would remove ALL

insulators run during the production. Of course, units that were cracked were

destroyed in a barrel at the end of the cooling lehr. Frank did take with him

those that might have small imperfections -- a weak embossing, air bubbles, a

little lopsided or those with small "potstones" (pieces of firebrick

that would break off into the furnace of molten glass), the last of which seemed

most prevalent in the amber run in 1977. "The mold never left my sight the

entire time we were in the glasshouse," said Miller.

The items from each production run that hold the most fascination for

collectors are the "warming pours". During each "turn" of

production, the pressmen take a five minute break every hour on the hour. When

they return to production, the mould is filled with molten glass three or four

times and not plunged, just to get the mould up to the correct temperature and

readied for the next hour's run. These large, solid glass commemoratives do not

cool well and tend to sag. Many will not survive the annealing process in the

lehr. Each year, the pours have numbered from a couple to a dozen that have

cooled in one piece.

When ordering a glass "turn", the Millers and the McDougalds were

at the mercy of the ability of the men operating the press. Whatever was

produced in the four-hour run was what was netted for the year's run. Most of

the early years averaged around 300 good insulators. Beginning in 1984, the

production rules changed at Mosser so that the insulators were ordered "by

the piece." This way, the number of units produced was guaranteed. As the

popularity of the commemorative has increased, the number of units ordered has

also increased to satisfy the number felt necessary to satisfy the collectors.

Frank Miller was often heard to say that "the mold never left his

sight" during production. He was unaware of some of the oddities that

occurred during his years of production. These happened during the runs at the

Overmyer-Perram and St. Clair glasshouses. However, there is a possible

explanation.

In a glasshouse; there are usually two rooms. The first one is where the

molten glass is gathered from the oven and placed into the mould, pressed, fired

and taken to the cooling lehr. A long trip down the moving belt of the lehr

(approximately 75 to 100 feet in length) finds the insulators emerging in a

second room where they are given a final inspection and packed into boxes. It is

entirely conceivable that the pressmen may have taken an opportunity at the end

of a run to make some oddities, while the mold owner was packing at the other

end of the lehr. Embossing a penny in the dome, spraying with carnival, using a

glass color from another oven to press several units, throwing cullet of a wide

range of colors into the mould or placing units into an acid bath to make some

bizarre "end of the day" samples is entirely possible. They can then

be placed on the back end of the lehr or even on a second, slower lehr belt and

never detected by the owner. So, it is entirely possible that shenanigans took

place undetected by the Millers. They could have left the building and returned

for the mould once it had cooled, and never been aware of the strange items

using their mould that have shown up in flea markets or found in the possession

of glass workers over the years.

The McDougalds have always stored the mould at Mosser Glass and taken only

the embossing rings out for erasure and re-engraving. And, since 1988, they have

not been present at Mosser for any of the productions runs. Mosser has been very

diligent about production, but there is always the possibility that strange

anomalies may surface at some point in the future. The only whimsical pieces

that have ever been created that are known to the McDougalds occurred in 1979

when one of the pressmen made about a half dozen ashtrays by putting cigarette

rests on the base of underpoured pieces.

1992 -- The Year of the Bonus

There were two years when Mosser Glass had some problems during the

production. The first occurred in 1992. The show hosts had requested a glass

color called "neodymium". It is a glass that is pink in natural

lighting, but turns a beautiful blue lavender color under fluorescent lighting.

Describing the color over the phone to the glasshouse brought an affirmation

that they knew the glass color and that they would be able make the color for

us. What could go wrong? We were choosing a color that was in their recipe

book.

1989 Commemorative Embossing:

20TH NIA CONVENTION

ALLENTOWN, PA JULY 14-16 1989

Dome Logo: Large keystone; Hawley signal; 20th show logo

The cost of the 1990 commemorative was $16.00 each.

1990 Commemorative Embossing:

21st NIA CONVENTION

PORTLAND, OREGON JULY 6-8, 1990

Dome Logo: Oregon state outline & five point star for Portland

The cost of the 1991 commemorative was $17.00 each.

1991 Commemorative Embossing:

22ND NIA CONVENTION

CEDAR RAPIDS, IOWA JULY 26-28, 1991

Dome Logo: Missouri Valley Insulator Club logo

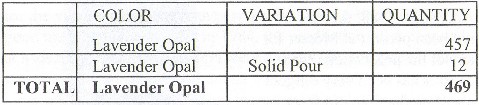

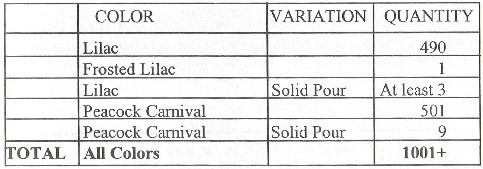

Well, the run was completed and nearly 500 insulators arrived at the

McDougald home. The first box was opened to find the exact same color as the

color run for the Rochester national show in 1983. Mosser checked their records

of glass colors run, and sure enough, they had run the same color as 1983. What

to do? Mosser suggested shipping back the lilac insulators to let them frost

their surface with an acid solution. So, one insulator was sent to them for

frosting to see if that would be acceptable. They returned one frosted

insulator, and it was decided that frosting the entire run was not acceptable.

"What production color are you doing right now?"

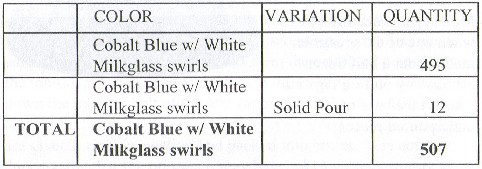

"Cobalt", was the answer. Cobalt had been run before. What other

suggestions?

"How about cobalt and then spraying them with carnival?" That

sounded like a better option. So, another order was placed for the 1992

commemorative...this time in cobalt carnival. Two weeks later another shipment

of insulators arrived.

"What do you want me to do with the first order in lilac?"

"They are yours, FREE," said Mosser. "It was our

mistake."

So, with each order for the 1992 commemorative received, a matching

"bonus" lilac was sent at NO CHARGE. The cost of the commemoratives

was $18.00 for the pair.

1992 Commemorative Embossing:

23RD NIA CONVENTION

ORLANDO, FLORIDA JUNE 19-21, 1992

Dome Logo: Central Florida Insulator Club logo

1993 Commemorative Embossing:

24TH NIA CONVENTION

DENVER, COLORADO JULY 2-4, 1993

Dome Logo: Triple Ridge Insulator Club logo

1994 - The Silver Anniversary

How does one make a silver glass commemorative? The McDougalds assumed that a

clear insulator could be sprayed with a color (similar to the way in which the

carnival coating is applied) at the time of pressing, and be annealed to the

insulator surface during cooling. Unfortunately, no such coating exists, and

Mosser Glass suggested that Custom Decco of Toledo, Ohio, be contacted to apply

a silver coating to the insulators after production. Four of the 1993 run were

sent to Toledo for a test of their coating procedures. The coating resembled the

color of chrome and not silver. Since the 1993 insulators were dark purple, it

was thought the lackluster color might be attributed to the color of the test

samples from that year.

The first move would be to run the commemoratives in clear glass, then find

out who could apply the correct coating using the actual insulator for the year.

The clear units were very sterile-looking pieces of glass when they arrived, so

the McDougalds began checking with collectors to see what they might suggest. .

Several people thought that we should contact a company which could plate the

glass similar to the way in which mirrors are manufactured. P.A. Clausing

Company in Skokie, Illinois, a firm that designed optics, parabolic mirrors and

telescope objectives was located. The project was explained. Two clear

commemoratives were sent, and again a chrome-looking coating was applied. Then

Clausing coated two small jars with a mirror application. Bingo! That was the

look needed.

The mirror-like coating of beryl aluminum was applied to the surface of each

insulator within a vacuum chamber. Only eight insulators could be treated at a

time due to the size of the chamber. Fortunately the process was started early

in the year so that the applications could be completed in time for the July

show in Houston. The cost of the 1994 commemoratives was $22.00 each.

1994 Commemorative Embossing:

25TH NIA CONVENTION

HOUSTON, TEXAS JULY 1-3, 1994

Dome Logo: Five point Lone Star with 25 in the middle

One may also wonder why the 30th NIA national show is coming up, and yet the

National Insulator Association is only 26 years old, having been formed at the

national show in Hutchinson, Kansas in 1973. (It probably never occurred to

Frank Miller, when he began the commemoratives in 1970, that a national

association would be formed.) The numbering of the commemoratives began with the

1970 national "meet", and continued to designate the national show

each year, even for those shows that took place before the NIA was formed. So,

the 1974 commemorative is embossed "NIA FIFTH NAT'L SHOW", and

subsequent years "6TH NIA CONVENTION", etc. In other words, the

commemorative "adopted" the NIA shows (or maybe the NIA

"adopted" the commemorative) after 1973. This may clear up the

confusion for the purists in the hobby who have observed that the NIA saw its

25th year in 1998.

As part of the 1995 national convention festivities, two members of the

National Insulator Association, Jack Riesselman and Jerry Turner were honored

for their attendance record at national shows. Nothing special had ever been

done since the "lucky seven" were honored at the 10th national show in

Denver in 1979. Both Jack and Jerry missed one of the shows during the first 10

years, so they were not recognized as part of the "Lucky Seven".

However, 1995 would be the 25th national show they had participated in. The show

hosts requested that two of the light cornflower blue commemoratives be plated

with silver so that they might be presented to Jack and Jerry at the awards

banquet.

P. A. Clausing was again contacted, but they would not do just two

insulators. They needed a minimum order of six commemoratives. The four extra

silver-coated pieces were given to each of the show hosts and one was retained

by the McDougalds.

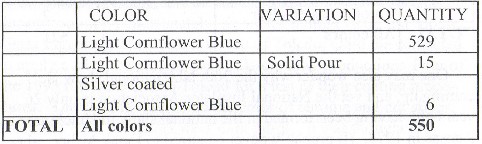

1995 Commemorative Embossing:

26TH NIA CONVENTION

MARLBOROUGH, MA JULY 14-16 1995

Dome Logo: Yankee Pole Cat Insulator Club logo

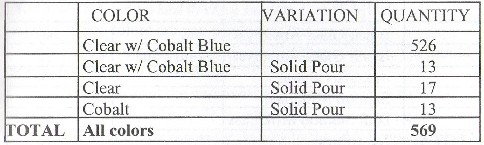

In 1996 the show hosts suggested a new idea for a glass color -- a clear

glass with a cobalt blotch, similar to the CD 155 Kerr insulators that were

produced in the early 1970's when cobalt cullet was added to the mould filled

with clear glass. A borrowed Kerr insulator was sent to Mosser. "No

problem, we can make that," was Mosser's reply. Why does that line sound so

familiar?

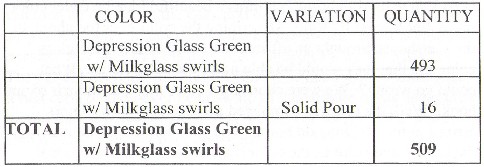

The two transparent colors stayed separated a little better in this run than

they did in the green and amber transparent colors of 1986. However, the cobalt

in clear glass was not nearly as dramatic as it had been in the Kerr insulators.

Both tanks of molten glass were tested prior to each "turn", resulting

in solid pours of each.

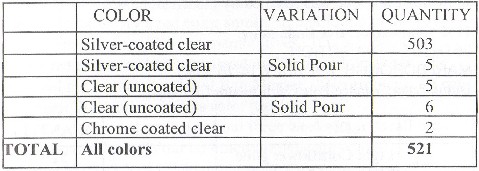

1996 Commemorative Embossing:

27TH NIA CONVENTION

LONG BEACH, CALIF JULY 19-21, 1996

Dome Logo: Sea horse show logo

So, one more time we would send a sample of what we wanted in the way of a

color to Mosser Glass. The 1997 show hosts requested that we try a red color

similar to that found in the 1972 private issue McLaughlin commemoratives. It is

a gorgeous opaque red and would be a great color if they could make it. We

borrowed the insulator and sent it to Mosser. "No problem, we can make

that. We used to make a color just like that."

The order was placed and about three weeks later, a call came from Mosser

Glass. "Your commemoratives are ready."

"How do they look? Did you get the red color to match?"

"Well, not exactly..."

"Did you run the entire order?"

"Yes, I'll send one up for you to look at, and I am going to reheat one

to see if the color is changed to a better red."

Several days later, a package arrives with two pieces; the RED and the RED

REHEATED. Imagine a bowl of Campbell's tomato soup -- a yucky salmon milkglass.

That was the color of the "red," and the heated red had lost all of

its sheen. They both were U-U-U-U-U-GL Y! Mosser destroyed the entire run. Black

glass amethyst was in the tanks which Mosser was carnivalizing for a customer.

Four carnival samples arrived by overnight mail, but it was determined that they

could not be distinguished from the 1992 peacock carnival. The 1997 run was

completed in black glass amethyst without the carnival coating. A major

disappointment when you thought you were going to have a red commemorative.

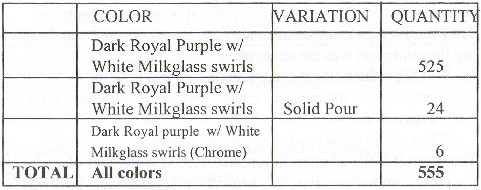

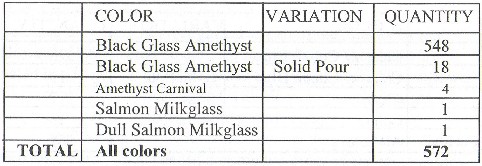

1997 Commemorative Embossing:

28TH NIA CONVENTION

CHICAGO, ILLINOIS JULY 25-27, 1997

Dome Logo: Illinois state outline logo

Over the years, commemorative collectors have suggested that actual

insulators be used to make one of the year's colors. The glasshouse could be

provided with enough damaged insulators to make enough cullet to produce a

"real insulator" commemorative if they were willing to do so. However,

since glassmaking is so very critical, Mosser Glass needs to be in control of

the elements used to make the batch of molten glass. And, insulators have far

too many impurities which could cause a lot of problems during production and

damage the tanks in which the glass is melted.

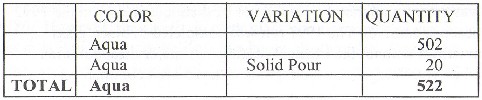

The color aqua had always been synonymous with insulators and was a color

that had not been run previously. Another customer who produces a short run

product at Mosser annually was using aqua glass in the spring of 1998, so it was

decided to have the commemoratives for Williamsburg run at the same time using

the same batch of glass.

1998 Commemorative Embossing:

29TH NIA CONVENTION

WILLIAMSBURG, VA JULY 31-AUG 2, 1998

Dome Logo: Chesapeake Bay Insulator Club logo with B&O insulator

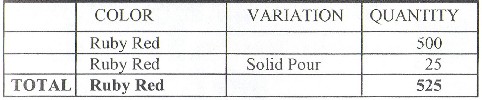

End of Three Decades -- Ruby Red

Ten years ago, Mosser Glass Company began constructing a tank that would

produce ruby red glass. And, it wasn't until a call was placed to their plant in

early January that the question was asked, "What colors are you producing

this spring?"

"We are in ruby red. Would you like that color? Is the mould ready with

the new embossing?"

The mould was at the engravers and Mosser was in ruby red. A quick call to

Cleveland, Ohio, where the engraving is done indicated that the mould was on its

way to the McDougalds in Chicago. When it arrived, it was sent by overnight

delivery to Cambridge, Ohio. The run in ruby red WOULD take place. The use of

gold chloride added considerably to the cost of production. The 1999

commemorative cost $25.00 each.

Ruby red -- a fitting celebration for our 30th year!

1999 Commemorative Embossing:

30TH NIA CONVENTION

SCOTTSDALE, AZ JUNE 25-27, 1999

Dome Logo: Grand Canyon State Insulator Club logo

This history was prepared from the commemorative production records and notes

by John and Carol McDougald. Statistics included in this presentation on

oddities during production were gathered by Kevin Lawless and John Hunsaker for

their noncompetitive exhibit of commemoratives and private issue insulators for

the 1998 national in Williamsburg, Virginia. Thank you, gentlemen. And, special

thanks to Clarice Gordon for assistance in the production of the text.

Copyright © 1999 by Crown Jewels of the Wire

|